Learn About Printer Architecture and Technology

Learn About Printer Architecture and Technology

Printing Architectures

There is an increasingly large number of innovative ways to put color onto a page. Ultimately, the goal of a print system is to quickly and inexpensively deliver quality color prints. The tradeoff between speed, quality, and cost provides segmentation where technologies fit the needs of specific applications. Where similar technologies are implemented, differences in quality emphasize the results of detailed design decisions.

An underlying rule for print quality is the concept of a minimum, application-specific quality level—a minimum quality level which varies with intended use and audience. (Similarly, there is a maximum quality level above which there is no further value for the application.) Only above this minimum quality level, where final output is acceptable for the particular application, can there be a valuable tradeoff between speed and cost.

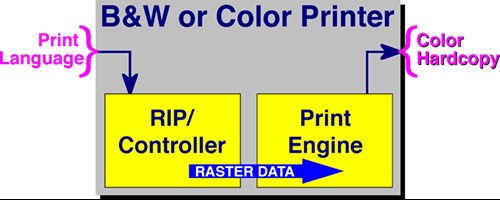

Printer quality can be affected significantly by both the capabilities of the Raster Image Processor, or “RIP”, and the marking Print Engine. Many print engines and RIPs are integrated into a single, stand-alone printing device; however, a range of engines and RIPs exist that can be combined to form custom printing solutions. Alternately, the RIP functions can be done in a host-based configuration environment and then sent in raster form to a marking engine.

Final print quality may be at least as much a function of the RIP as of the print engine. There is an intrinsic difference between characteristics of the RIP, characteristics of the print engine, and the impact of each on quality. Certain digital image processing techniques may affect the quality of the printer’s output; for example, image processing can increase effective resolution considerably. With continual embellishments and improvements on the basic technologies, color printing has jumped beyond mere technological advances, becoming more responsive to the demands and subtleties of print quality in the quest for higher performance at lower cost.

The basic color print engine technologies may be grouped into several general classifications:

- Thermal (Wax Transfer, Dye Sublimation, Photo Sublimation)

- Inkjet (Solid, Liquid, Continuous)

- Electrostatic (Xerography, Liquid TEP, ElectroInk, Direct)

- Others (Photographic, Digital Offset, Dry Silver, etc.)

The Color Hardcopy Quality Factors (CHQF) Study Report Series analyze products in all four classes. These technologies cover most of the range of color marking engines from low cost inkjets through high-quality pre-press proofers to high-speed digital presses.